Industrial Coatings

Industrial coatings protect manufactured substrates from corrosion and other sources of damage during a product’s lifecycle. They can also add to a product’s aesthetic value.

Manufacturers can complete finishing operations in-house or contract out their finishes. Either way, they should make sure they carefully follow the powder coating process and equipment manufacturers’ guidelines for optimum results.

Specialty Coatings

For surfaces where paint isn’t enough, specialty coatings offer an array of options. Whether it’s metallic epoxy for a commercial garage floor, a durable below-grade deck coating system, or a decorative concrete stain for a residential driveway, these products can provide the extra durability, corrosion resistance, and aesthetic appeal you need.

Specialty coatings can be applied to metal surfaces that need extra protection against extreme temperatures or chemicals. They can also help improve a surface’s ability to resist abrasion, scratching or galling. A variety of finishes are available to meet the specific needs of different types of applications, from abrasion resistant and high gloss to chemical and impact resistant.

A number of different processes are used to apply these special coatings. Depending on the desired functional outcome, these processes can range from a simple paintbrush to expensive machinery that uses thin film deposition techniques. These technologies produce high-density, functional films that are resistant to oxidation and other environmental degradation.

Industrial coatings must be cured properly for optimal performance. This requires adherence to the manufacturer’s temperature specifications, as well as precise drying and cure-through times. Improper curing can cause the coating to fail, and it may even damage the substrate beneath.

Fluoropolymer coatings are a unique type of protective layer that offers many additional properties beyond corrosion resistance and abrasion durability. These coatings are extremely durable and can withstand very high temperatures, while also offering anti-stick, non-wetting, dry film lubrication, low friction and electrical resistance.

Molybdenum coatings are a two-coat system that combines high-performance resins with molybdenum disulfide lubricant. These coatings are very hard and can withstand a high load-carrying capacity, while also providing excellent abrasion resistance and anti-galling.

In addition to their technical properties, these coatings can offer an attractive appearance and an excellent bond with the substrate. They can be designed in a wide range of colors and effects, from solid brights to deep neutrals and blending shades. A wide variety of substrates can be coated with these materials, including glass, metal, mirrors and plastics. These coatings are also very easy to clean and maintain, making them an excellent option for high-traffic areas in health care, hospitality and retail facilities.

Electrostatic Coatings

Using the power of static electricity, electrostatic coating adheres paint or coating particles to metal by creating a positive charge on the particle as it is sprayed and a negative charge on the surface of the metal. This attracts the particles to the metal and results in an exceptionally strong, even coat with minimal sagging or runniness. The electrostatic bond also minimizes the amount of “overspray” (spray that lands on areas other than what is being coated) that occurs with conventional spray painting techniques.

In addition, electrostatic liquid painting is very versatile, meaning that almost any color can be applied to metal using this technique. Unlike powder coating, which requires pieces to be immaculate in order to receive an ideal finish, electrostatic liquid painting can be performed on a wide range of materials and conditions—as long as they are free of oils, dirt, moisture, residue, dust, or other debris. This makes this type of coating a popular choice for the repair and restoration of old items that would otherwise be thrown away.

Another advantage of electrostatic painting is that it can be completed on-site. This is a huge benefit for pieces that are too large or dangerous to transport to a facility to be powder coated, or those that require heat after being sprayed or dipped in order to cure the finished product. It also means that desks, file cabinets, lockers and more can be spray painted on-site without having to be moved or taken apart – saving you time and money.

Powder coating is a durable, low-maintenance alternative to traditional liquid paint that can be applied to both ferrous and non-ferrous metals. It uses the law of attraction between positively and negatively charged particles to adhere to the metal surface, which is then cured in an oven for an extremely durable and long-lasting result.

The process of powder coating is much faster than conventional painting, which saves on both labor and material costs. Additionally, it does not use solvents, which eliminates the need for waste management and disposal—making it an ecologically friendly option.

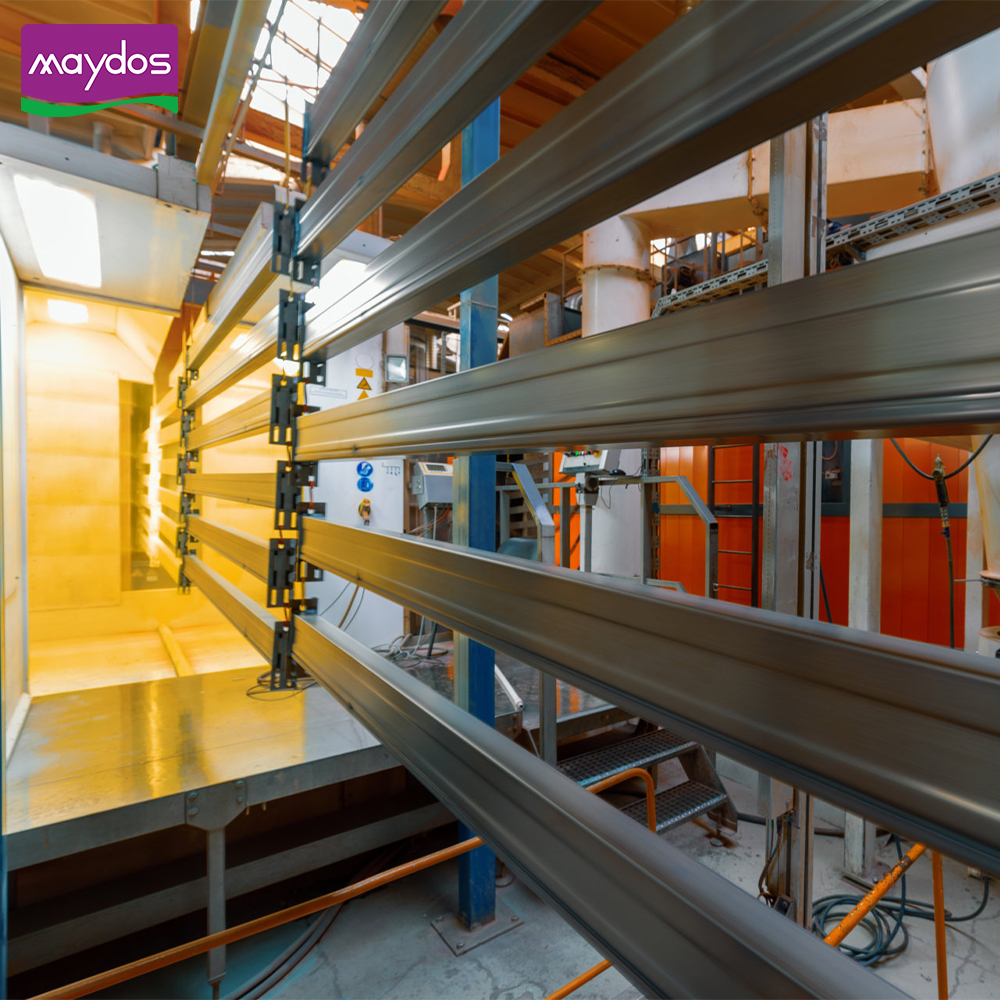

Powder Coatings

Powder coating is applied to metal surfaces and it’s a popular alternative to liquid finishes. It’s available in thousands of different colors and is suitable for both protective and decorative applications. It’s also capable of being formulated in different textures that can hide surface imperfections. This dry finishing process is ideal for a wide variety of products, including furniture, cabinets, enclosures, and trailers.

Prior to the powder coating application, a product’s surface needs to be thoroughly cleaned. This includes removing any dirt, oil, or grease from the item’s substrate. Any bolts, screws, or nuts should be removed as well and the item needs to be properly masked. It’s important that items are free of any binding materials because if they’re not, the powder coating won’t adhere to the object.

Unlike liquid paints, powder coating does not contain any solvents. As a result, it doesn’t release volatile organic compounds (VOCs) into the air during the curing process. This benefit has helped the powder coating process become increasingly popular as manufacturers seek to reduce their environmental impact.

As a powder, coating material can be applied to an article’s substrate using a spray gun that uses electromagnetic charges to attract the powder to the item. The powder is aerated by a porous plate in the base of the spray container, and it’s then pumped or blown into an aerated dust cloud that’s ready for use.

Once the article is coated, the powder is cured with heat. The exact curing schedule depends on the thickness of the coating and the article’s material. It’s possible to cure the powder coat with convection bake ovens, infrared curing ovens, or even with laser curing processes.

Powder coating is a sustainable finish that’s durable and long-lasting. It’s also easy to clean and maintain, and it provides a great deal of resistance against corrosion. This type of finish is ideal for medical devices, architectural applications, automotive refinishing, and other industrial parts. It’s also used to coat appliances, bicycle parts, and household and office furniture. Once the coated metal is cooled, it can be assembled, packaged, and shipped.

Spray Coatings

In the aerospace industry, thermal spray coatings are used to protect and repair aircraft components. The coatings can also be applied to extend the life of new parts before they enter service or to restore worn parts for improved performance. These coatings provide protection against corrosion, fatigue, oxidation and high temperatures. They can also be used to change the appearance of a component, improve electrical or tribological properties, and replace worn material.

The thermal spray process involves sprayed particles of metallic materials or ceramics that are fused with the substrate to form a strong, solid-state bond. The coatings can be applied to surfaces of various shapes and sizes, and a wide variety of materials is available for depositing as coatings. Metals and metal alloys, oxide and non-oxide ceramics, plastics, and cermets are some of the most common coating materials. The deposition process for the coatings is rapid and the coatings can be deposited to very thick layers.

The absence of high temperature particle heating during the deposition process eliminates oxidation, promotes retention of the properties of the original feedstock particles, induces low residual stresses in the coating, and facilitates the use of thermally sensitive materials such as polymers. The ability of the thermal spray process to deposit dissimilar materials, such as cermets, provides tremendous flexibility to the user.

Coating Factory offers both HVOF and plasma sprayed coating services to provide the best solutions for your needs. Our skilled team can offer custom applications, repair of existing components, and other services to help ensure the long-term performance of your equipment. We can also assist you with the selection of the right thermal spray process for your application.

In addition to enhancing the performance and longevity of your aircraft components, we can also provide coatings for automotive applications. We can coat a wide range of materials, including engine components, fuel systems, body panels and exterior components. We can even coat components with different colors to match your brand or design aesthetic.

The aerospace sector is one of the biggest markets for the thermal spray market, as it utilizes this type of coating to enhance the quality of its components and to extend their lifespan. Some of the most important applications include gas turbines, landing gears, and actuation systems. The aircraft industry is continuously looking for ways to improve its performance and efficiency, which means using more lightweight components with higher strength-to-weight ratios. These lightweight materials require specialized coatings to protect them from corrosion, wear and fatigue.