Epoxy Floor Paint

You have a few options when it comes to choosing the right epoxy floor paint. In this article, we will look at the various types of this type of paint, their applications, cost, and durability. Once you decide on the type of epoxy floor paint, it’s time to start looking at its application. The first step is to find out how durable the product is. Make sure to test it first and allow it to dry thoroughly. Applying a second coat may require a second day.

Durability

If you are looking for a coating that will last for years, you should look into epoxy floor paint. This type of coating is much stronger than traditional paint and is often used for locker rooms and industrial floors. It is also highly stain resistant and easy to clean, making it a good choice for these areas. However, paint is a cheap and easy option, and it doesn’t have to take much abuse. In fact, it’s often easier to apply than epoxy coatings, so a professional is recommended.

Although you should always be aware that chemicals from your car and housework can affect the quality of an epoxy coating, most types are heat-resistant and can withstand 200 degrees Fahrenheit. However, higher grades of epoxy will tolerate higher levels of heat, and some phosphorus-containing epoxies have better heat resistance. These properties make them excellent for kitchen and garage flooring. Once applied, it is essential to allow time for the coating to fully cure.

Another feature of epoxy that makes it so strong is its shock-resistance. Heavy objects that fall on the floor will not damage the coating. This is also true for vehicles. You can park your car on an epoxy-coated concrete surface without worrying about it crashing and chipping. It will also stay intact even if heavy items fall on it. Its shock-resistance is another feature that makes it an excellent choice for parking lots and car parks.

An epoxy floor paint has several benefits over other flooring materials. The resin is made of short chain polymers and an epoxide group. It is a two-component product and must be mixed before application. This process limits the time and temperature it takes to cure. A 100% solid epoxy floor paint will remain 100% solid on the floor while a 50% solid epoxy will have less product left on the surface after curing.

Lastly, epoxy floor paint has a high scratch-resistant quality. A thicker layer of the coating can even cover minor imperfections in the concrete. If you are looking for a floor paint that will last a long time, epoxy is an excellent choice. The coating is extremely easy to clean and requires only a mild cleaning solution. Once it is dry, the dirt can be broom-cleaned up easily. If it’s not, you can always clean the floor with a soft broom and rinse it off.

Another advantage of epoxy floor paint is its versatility. It can be professionally installed or you can do it yourself if you know how. Before applying epoxy, make sure that the surface is clean and ready to be coated. It is best to test the old concrete for any previous layers of epoxy or sealant. If you notice water beads on the concrete, then it’s probably not ready for the epoxy coating. However, if it looks great, it’s worth the trouble.

Cost

The construction cost of epoxy floor paint varies according to the type, thickness, and number of coats required. The application technique also affects the cost. It can be applied by squeegee, roller, trowel, or sprayer. There are many types and brands of epoxy floor paint available in the market. Each type has its own unique pricing, so the best way to find the right one for your project is to compare prices from various suppliers.

When you choose a product, it is necessary to prepare your floor for application. You must first ensure that the surface is smooth and free of cracks or other defects. After the preparation stage, you must apply a primer coat, which provides a good base for the epoxy to adhere to. The application process will take approximately two days. The primer coat will be applied on the first day, and the final coat will be applied the second day.

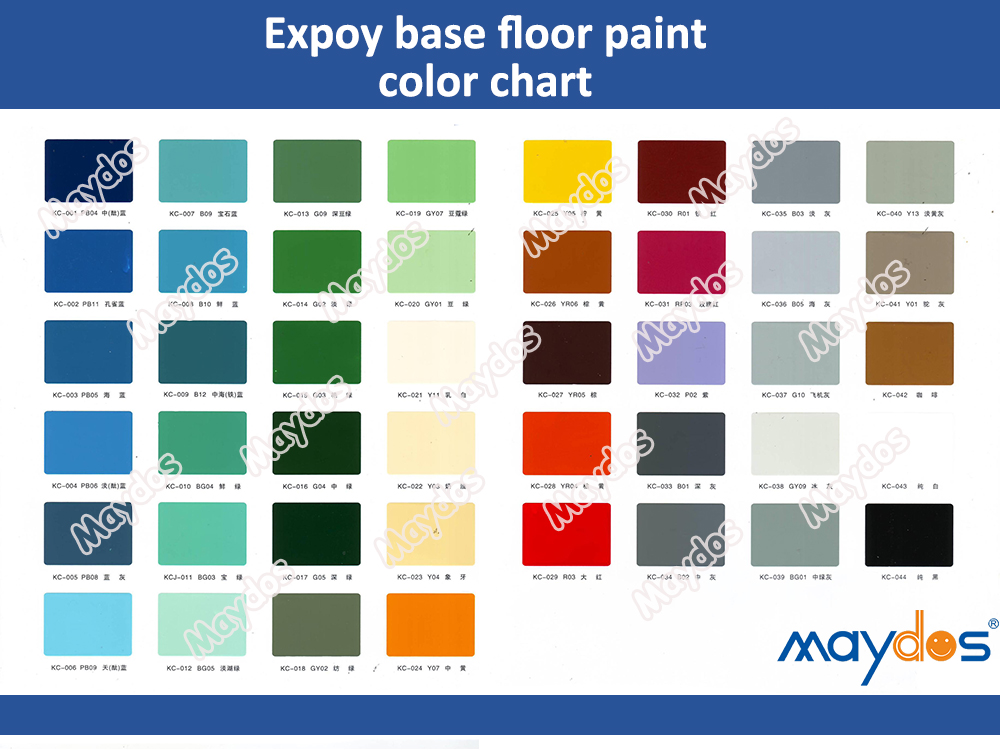

You can choose the color of the epoxy floor paint. It can come in neutral colors like white, grey, or clear. The brighter colors, such as red or yellow, can be a bit more expensive, but they look fantastic. You can also opt for decorative flakes to give the flooring a unique look. One pound bag of these flakes typically costs around $10, and covers about 125-250 square feet of floor space.

DIY epoxy floor coating is a great way to save money. If you know how to do these things, it can save you anywhere from 10 to 40% on the cost of an epoxy floor paint. You’ll also save money by avoiding the need for expensive professionals. The best part is, DIY epoxy flooring can be completed at home and will save you from paying a fortune on hiring a contractor. But you must be sure that the product will be durable and long-lasting.

There are two types of epoxy: solvent-based and water-based. Solvent-based is more durable and resistant to petroleum-based products. However, you must wear a respirator if you want to apply this kind of floor paint. Water-based epoxy is cheaper, but it must be reapplied every year or two. Water-based epoxy is ideal for low-traffic areas. However, the cost is still considerably higher than solvent-based epoxy.

Commercial-grade epoxy paint will cost between $3 and $12 per square foot. It is important to choose the highest-quality product for durability, and this will save you money in the long run. You can save money by preparing your concrete prior to applying epoxy. You can also choose between water-based and solid epoxy. However, it is important to note that the latter is more expensive, and can cost as much as $1,500. And it’s also important to note that a water-based solution will not be as strong as a 100% solid epoxy coating.

Application

Epoxy floor paint is a popular coating option for concrete floors. Its oil-based formula makes it perfect for floors that receive a lot of moisture. Once applied, the coating dries to a smooth, glossy finish. Epoxy paint is highly durable and resistant to chemicals and the sun’s rays, so it is an excellent choice for outdoor applications. Applying epoxy paint to a wooden floor requires specific preparation techniques.

The first step is to clean the floor. Remove any stains or scratches from the surface. Then, apply the first coat of epoxy floor paint. When applying the second coat, it is important to make sure the floor is completely dry. Before completing this step, it is a good idea to test the concrete for previous sealant or epoxy coating. If you see beads of water on the surface, the concrete is not ready for epoxy coating.

To prepare the floor for epoxy floor paint, it is recommended that the concrete temperature is 55 degrees Fahrenheit or lower. Before painting, you should clean away old paint and oil stains. If stains are particularly stubborn, you can use a scrub brush or degreaser to remove them. To avoid damaging the floor, ensure that the concrete surface temperature is within the recommended range. Then, follow the steps outlined in the manufacturer’s instructions.

Preparing the floor for epoxy coating involves several steps. It is crucial not to rush the preparation. This process can take several days. It is essential to avoid rushing the process, as it can be difficult to apply the coating if you don’t prepare the floor properly. If you don’t follow these steps, your floor will end up looking ugly and will not last long. Once the surface is ready, you can start applying the epoxy coating.

When choosing the right floor coating for your garage, consider the use of chemical-resistant paints. Epoxy coatings are resistant to chemicals from housework and cars. If you keep your garage clean, the paint will last for up to five years without any problems. Epoxy is also ideal for areas where you want to segregate traffic by highlighting specific traffic patterns. If you have a large collection of cars, this may require extensive work.

Once you have chosen the right epoxy floor coating for your project, the next step is to prepare the surface for the final coat. To get the most out of your finished floor, the surface must be smooth and free of holes. After applying the first coat, you should use denatured alcohol to clean the area and make sure all of the surfaces are smooth. Using a roller will help the process along. Then, you need to wait 12 to twenty-four hours for the coating to dry.